Wolfertschwenden, 5 March 2019 – At IFFA 2019 MULTIVAC will be demonstrating its expertise in complete lines and automation for the meat processing industry. Under the banner of “The DNA of Better Packaging and Processing”, the solution provider will be showing in Hall 11.1 several fully automated lines for the slicing, portioning and packing of different meat and sausage products. In addition to this, live demonstrations of MULTIVAC slicers and TVI portioners will take place in the MULTIVAC Processing Tent in front of Hall 11.

Thanks to the systematic expansion of its product range in the direction of Processing, MULTIVAC can now offer its customers high-performance equipment, both as individual components and integrated solutions, from one source for the processing and packing of meat and sausage products. As regards the areas upstream of the packaging machine, the product range extends from slicers and portioners through to transport conveyors of all types and right up to handling modules for converging or orientating the products and loading them into the packs.

Three packaging lines will be exhibited in Frankfurt, and a slicer or portioner will be integrated in each of them. In addition to the efficient linking of the slicing or portioning system with the downstream packaging machine, particular attention must always be paid to ensuring, that the sliced or portioned products are transferred gently and accurately into the pack cavities. MULTIVAC offers various groundbreaking solutions for this purpose, such as for example the MULTIVAC Horizontal Loader or various handling solutions, which ensure that the sliced or portioned products are loaded gently and hygienically into the pack cavities – and all this with the minimum of footprint.

In addition to this, various solutions are integrated into the lines for pack labelling, inspection, converging and box packing. All the system components, which are matched perfectly to each other, can be controlled via one single control terminal on the packaging machine. The result is a precise, reproducible and transparent control process, which can be operated with the minimum of effort.

A thermoforming packaging line for sliced products will be shown at the trade fair, and this consists of a R 245 thermoforming packaging machine and a high-output S 1600 slicer. The S 1600 is equipped with fully automatic central loading and, thanks to its innovative slicing technology, enables a very high slicing speed of up to 1,600 highly accurate slices per minute to be achieved. The portioning system on the machine can perform virtually any portioning task – from precise placement of sausage, ham or cheese slices in shingled, straight or offset stacked portions, through to the shingling of wafer-thin cut product, and right up to the folding of individual slices.

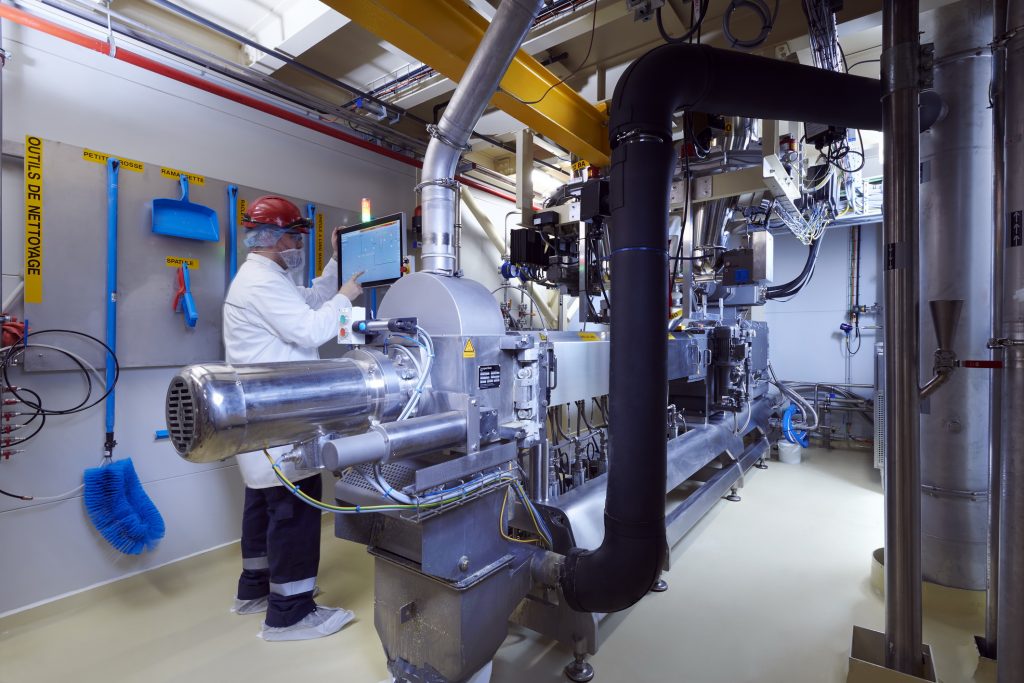

An automated thermoforming packaging solution for portioned fresh meat will also be shown at the trade fair. A R 245 thermoforming packaging machine is similarly at the heart of this line. A GMS 1600 twincut portioning machine, which is integrated in the line, is capable of highly accurate portioning of fresh or frozen meat products (with and without bone). The portioner offers maximum yield and portioning quality thanks to its three-dimensional forming – and it also features a significantly reduced footprint as well as a high level of cost-effectiveness, since it does not require an additional meat press.

MULTIVAC will be exhibiting an automated traysealer line for packing sliced fresh meat, which includes the highly flexible GMS 520 singlecut portioning machine. The T 800 traysealer, which can be scaled to individual requirements, is particularly suitable for producing MAP packs and MultiFreshTM skin packs in large batches. At the trade fair the packing of sliced meat products will be shown in PaperBoard skin packs. These MultiFreshTM packs are based on pre-cut board sheets, which not only have an attractive appearance but can also be easily recycled. The TVI portioner can process all types of red meat and poultry in any consistency and to any portion size, and always optimised for weight and product trim, as well as at a low level of processing cost. It ensures that the highest product quality is always achieved, even at high throughput, in terms of the cutting, forming and shingling of the product. At the end of the process a full-wrap label is automatically applied to the PaperBoard skin packs by a L 310 conveyor belt labeller.