Page 72 - FoodFocusThailand No.206 MAY 2023

P. 72

SOURCE OF ENGINEER

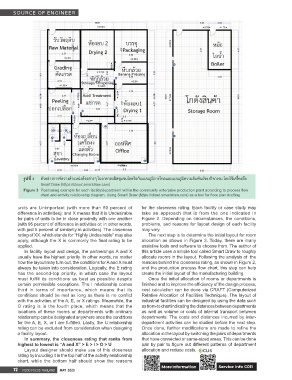

รููปที่่� 3 ตััวอย่่างการจััดวางตัำาแหน่่งห้องตั่างๆ ใน่อาคารผลิิตัชุุมชุน่โดย่อิงกับแผน่ภููมิการไหลิแลิะแผน่ภููมิความสััมพััน่ธ์์ของกิจักรรม โดย่ใชุ้เคร่�องม่อ

Smart Draw (https://cloud.smartdraw.com)

Figure 3 Positioning example for each facility/department within the community enterprise production plant according to process flow

chart and activity relationship diagram. Using Smart Draw (https://cloud.smartdraw.com) as a tool for floor plan drafting

units are Unimportant (with more than 50 percent of for the closeness rating. Each facility or case study may

difference in activities); and X means that it is Undesirable take an approach that is from the one indicated in

for pairs of units to be in close proximity with one another Figure 2. Depending on circumstances, the conditions,

(with 95 percent of difference in activities or, in other words, problems, and reasons for layout design of each facility

with just 5 percent of similarity in activities). The closeness may vary.

rating of XX, which stands for “Highly Undesirable” may also The next step is to determine the initial layout for room

apply, although the X is commonly the final rating to be allocation as shown in Figure 3. Today, there are many

applied. assistive tools and software to choose from. The author of

In facility layout and design, the partnerships A and X this article uses a simple tool called Smart Draw to roughly

usually have the highest priority. In other words, no matter allocate rooms in the layout. Following the analysis of the

how the layout may turn out, the conditions for A and X must reasons behind the closeness rating, as shown in Figure 2,

always be taken into consideration. Logically, the E rating and the production process flow chart, this step can help

has the second-top priority, in which case the layout create the initial layout of the manufacturing building.

must fulfill its conditions as best as possible despite Once the initial allocation of rooms or departments is

certain permissible exceptions. The I relationship comes finished and to improve the efficiency of the design process,

third in terms of importance, which means that its cost calculation can be done via CRAFT (Computerized

conditions should be met as long as there is no conflict Relative Allocation of Facilities Technique). The layout of

with the activities of the A, E, or X ratings. Meanwhile, the industrial facilities can be designed by using the data such

O rating is in the fourth place, which means that the as from-to chart indicating the distances between departments

locations of these rooms or departments with ordinary as well as volume or costs of internal transport between

relationship can be designated anywhere once the conditions departments. The costs and distances incurred by inter-

for the A, E, X, or I are fulfilled. Lastly, the U relationship department activities can be studied before the next step.

rating can be excluded from consideration when designing Once done, further modifications are made to refine the

a facility layout. allocation in the layout by switching the pairs of departments

In summary, the closeness rating that ranks from that have connected or same-sized areas. This can be done

highest to lowest is “A and X” > E > I > O > U pair by pair to figure out different patterns of department

Layout designer should make use of this closeness allocation and reduce costs.

rating by including it in the top half of the activity relationship

chart, while the bottom half should show the reasons

More Information Service Info C011

72 FOOD FOCUS THAILAND MAY 2023

21/4/2566 BE 11:09

66-72_Source of eng_����.indd 72

66-72_Source of eng_����.indd 72 21/4/2566 BE 11:09