Page 51 - 146

P. 51

STRONG QC & QA

to know about preparation and prevention measures as well. plan, manufacturers should also consider on the area where the products

In order to prevent the allergen, general food processing indirectly touched on surface, utensils, or any areas that may be affected

plants will have preventive control measure based on quality from the allergens can cause of contamination. It was found that wet

control systems such as GMPs, HACCP, and FSMA, etc. to cleaning method could better remove the inherent allergens than dry

manage and control allergens in the product, starting with hazard cleaning method.

analysis and risk assessment and other measures. For instance, The most effective allergen removal method is rinsing and cleaning

those are the separation of each division in the factory, the method. After cleaning, there should be a proven measure to ensure that

determination of specific areas for allergens by drawings the no allergen residues are remained in order to reduce risk of cross

enclosed area, separate room, set up specific shelves, separation contamination from surface to the products.

of equipment/tools, reduce the movement of goods or materials,

as well as restrict specific areas for food allergen, including There are several sterilization methods in monitoring the efficiency of

ingredients or finished products in an attempt to reduce the the cleaning methods including monitoring with naked eye, ATP surface

possibility of cross-contamination. test, a total protein visual test that rapidly detects protein residues left on

In case manufacturers cannot restrict the area dedicated to product contact surfaces after cleaning.

allergen products, they should have a well plan that can reduce Preliminary monitoring with naked eye should be done in the production

the chance of contamination by producing products that are area, equipment, and machine after cleaning and waiting until the surface

allergen-free, and then produce the product with allergen in the is dry because the stain is not visible when the surface is still wet. If

final procedure. Or else, manufacturers should draw a long-term cleaning and removal of allergens on the surface is effective, no residue

plan for producing the product with allergen in large amount and should be found. However, there are many limitations of monitoring with

clean up the area at once time. Also, along the production naked eye, other effective and sensitive monitoring methods should be

schedule, proper frequency and method of cleaning should be done concurrently.

drawn during the transition procedure, while rework-in process

should be controlled.

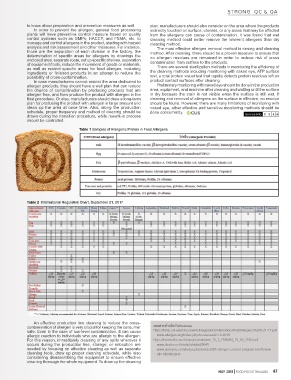

Table 1 Samples of Allergenic Protein in Food Allergens

Table 2 International Regulation Chart, September 21, 2017

An effective production line cleaning to reduce the cross-

contamination of allergen is very crucial for keeping the consumer เอกสารอ้างอิง/References

safe. Even in the case of low-level contamination, it can cause https://farrp.unl.edu/documents/Regulatory/International%20Allergens%209-21-17.pdf

allergic reaction to individuals who are allergic to the allergen. www.allergen.org/index.phpAcceessed2-18-2018

For this reason, immediately cleaning of any spills wherever it https://home.kku.ac.th/uac/journal/year_15_3_2550/04_15_03_2550.pdf

occurs during the production line, storage, or relocation are www.doctor.or.th/article/detail/5645

needed by focusing on effective cleaning as well as separate www.isotoyou.com/index.php/article/285-allergen-control-program.html?show

cleaning tools, draw up proper cleaning schedule, while also all=1&limitstart=

considering disassembling the equipment to ensure effective

cleaning thorough the whole equipment. To draw up the cleaning

MAY 2018 FOOD FOCUS THAILAND 47