SMART

PRODUCTION

55

MAY 2017 FOOD FOCUSTHAILAND

(Antioxidant).For redpepper, thedryingprocesscanmaintain redness

and capsaicin content, while reducing the degradation of carotenoid

content, an important yellow pigment in pineapple. It also helps slow

the browning and other reactions that affect quality deterioration.

Freeze drying technique is becoming increasingly popular in food

processing industry toaddvalue to foodproductsas it providesahigh

qualityofproducts.Freezedryingcauses lessdamage to thesubstance

while the contraction of the cell structure is very small. In addition,

smells, flavors, and color of the food content generally remains

unchanged. Also, the appearance of the dried product remains the

same as it’s fresh. However, freeze-drying is a relatively more

expensiveprocess thanothermethods, itoften reserves for thehigher

economic value products. Currently, the machines for sublimation

freezedrying technologycanbemanufactureddomestically, resulting

in lower production costs and is more likely to bring into use at the

industrial level.

รู

ปที่

2

แผนผั

งวั

ฏภาคของน�้

ำและสภาวะการอบแห้

งด้

วยวิ

ธี

ต่

างๆ

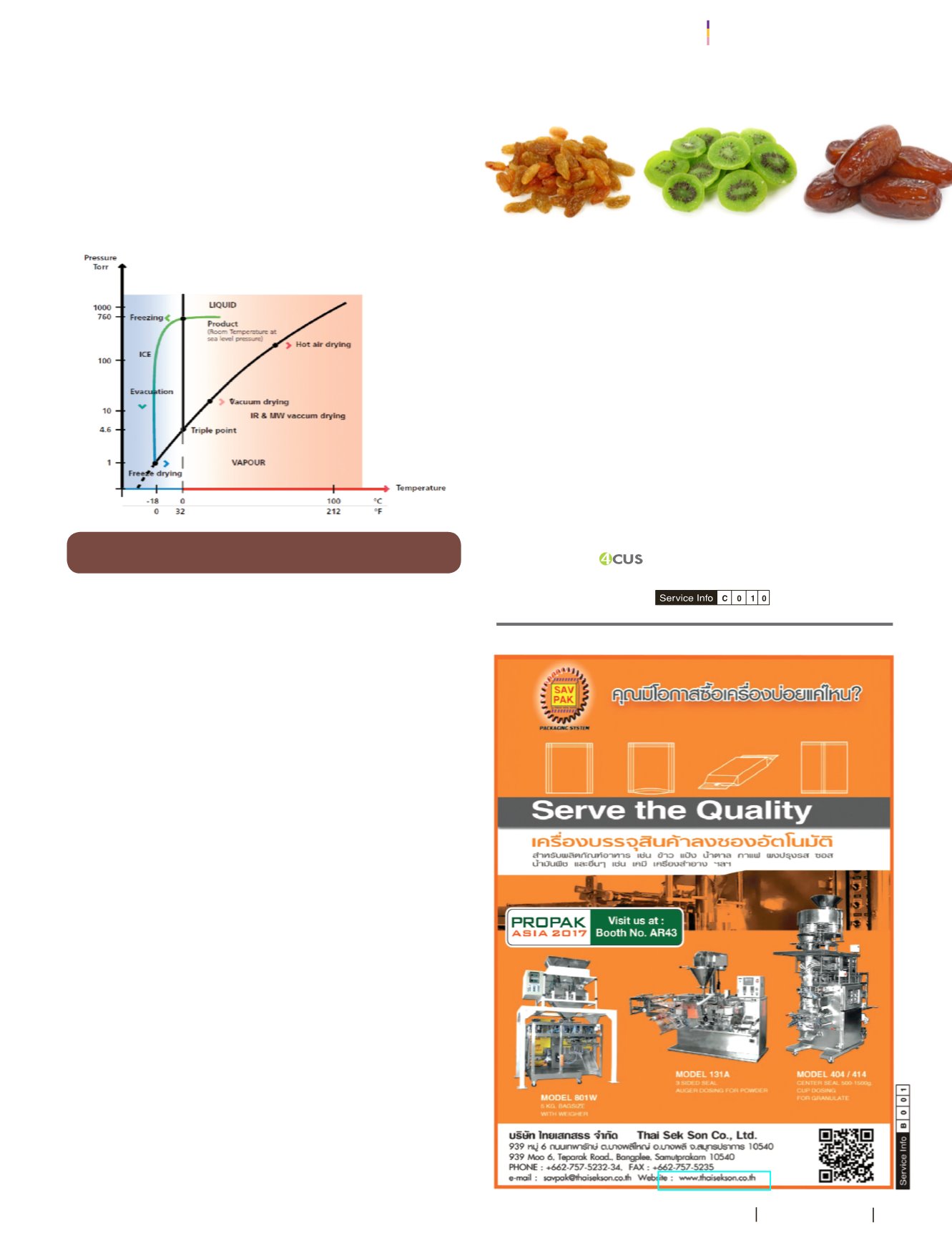

Figure 2

Phase diagram of water and dryingmethods condition

ที่

มา/

Source:

Creating a vacuum condition by removing air from the system

can lower the temperature of the water phase. During vacuum

formationof thesystemwhile theair isbeingevacuated, it givesan

advantage inmaintaining theproductqualities.Since thecontinuous

air removal reduces theoxidation reaction, it results in lossofproduct

quality during the drying process, where oxygen is the primary

reactant. Nowadays, combineddryingwithmechanical energyand

thermal energycancreateavacuumconditionat 10-20MPaor can

change thewater phaseof theproduct in the temperature rangeof

55-65 °C. Drying can be divided by heat transfermechanisms and

heatingenergy resources suchas vacuumdrying, electromagnetic

drying (Infraredormicrowavewaves),vacuumsystem, respectively.

However, theabove-mentionedhybriddryingsystem isachange

in the phase of the water from liquid evaporated to vapor. In this

step, if a vacuum pressure falls below 610.5 Pa, it will come to a

condition that thewaterphase insolidstatuscanbesublimeddirectly

to vapor phase. Therefore, for the freeze-drying techniques, food

products will be frozen at -10 to -18 °C, then the pressure in the

system will be reduced to absolute vacuum as described above.

This brings about a change in the vacuumpressure condition. The

food gets heated under such conditionwhile ice crystals in frozen

foodwill sublimateor change itsstatus fromsolid tovapor,whereby

the amount of ice crystals in the food becomes sublimated and

evacuated by a vacuum pump.

Today, drying byMultiprocessingDryers has been used at the

industrial level todevelopqualitystandards foragricultural products

and dried food products in both batch and continuous forms.

Especially for drying herbs, this technology can help increase the

valueof theproducts, suchas turmericand

Ganoderma

, which the

drying process helps to reduce the rate of oxidative deterioration

happens at the low temperature. Therefore, evaporation under

vacuum can occur at low temperatures (Depending on the vacuum

condition of the system). Figure 2 shows evaporating points

from various drying methods. This is to say, in hot air drying, the

evaporation of water contained in the product occurs at the

atmosphericpressure (Combinedmodesof heat transfer dryersand

Multistage dryers).