SMART

PRODUCTION

49

JAN 2017 FOOD FOCUSTHAILAND

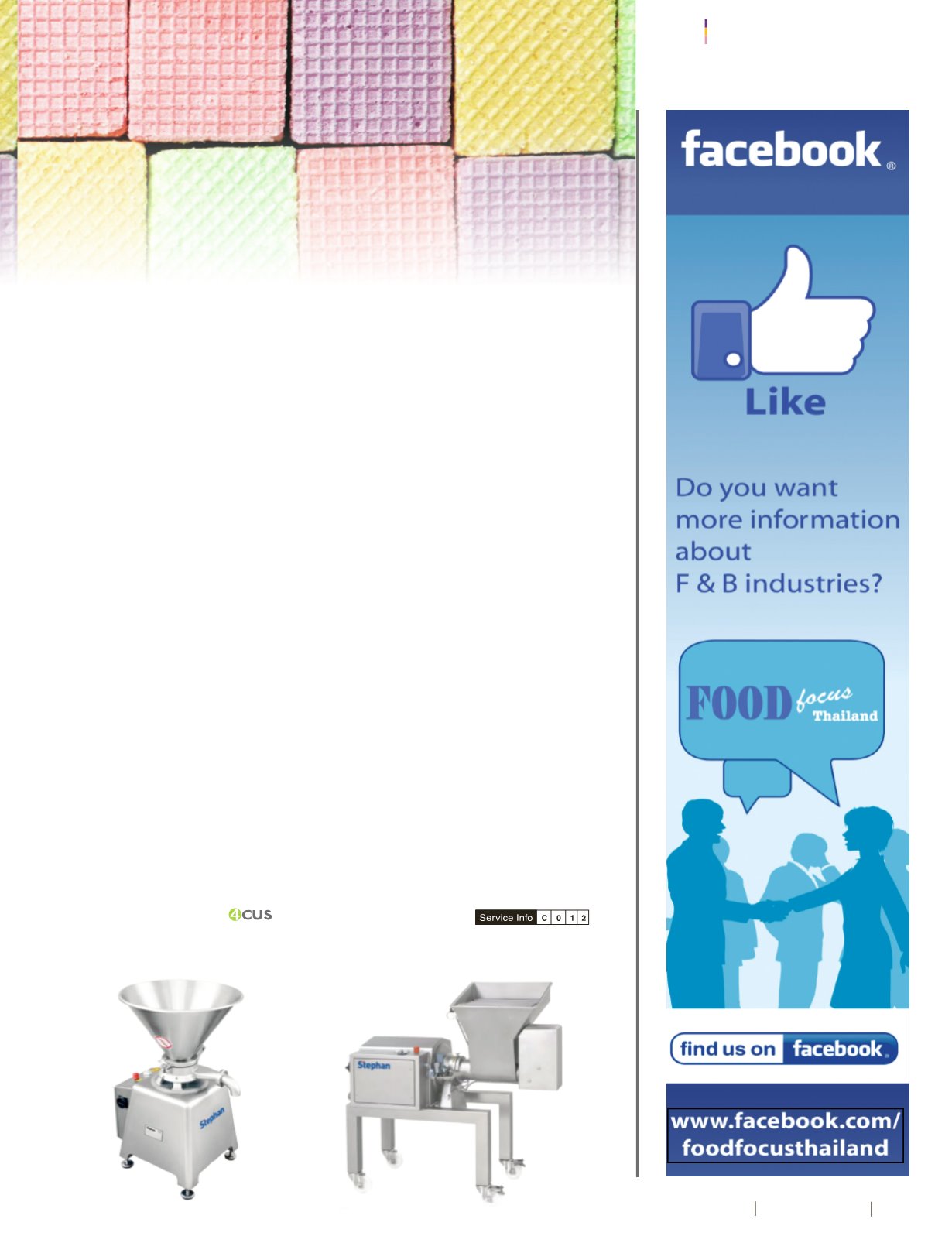

With the innovation of engineering, a new technology has been created to solve above

mentioned issuesandalsohelpmanufacturers to increaseefficiencywith leanmanufacturing

concept.Amodernandsophisticated cookingbowl shown infigure1candoa lot of things in

onemachine includingcoursegrinding, homogenousmixingand reserve the indirect heating

or cooling via jacket, etc. This machine can also receive the ingredient during mixing or

cooking via thedosinghopper by vacuum system in thebowl without aneed toopen the lid.

Highlight of modern cooking bowl is that the cooking process is always done under vacuum

condition which allows the texture of product to be consistent without air bubble inside as

shown in the figure 2. By this reason, it will give a longer shelf-life because there is no air

bubble in products to accelerate any chemical reaction and the growth of microorganisms.

Adirect stream injection, which is available as an option, will give a good heat exchanging

reaction, and help eliminate a burnt-smell issue from products. Stream used is also filtrated

by the international standard steam filter to ensure product safety.

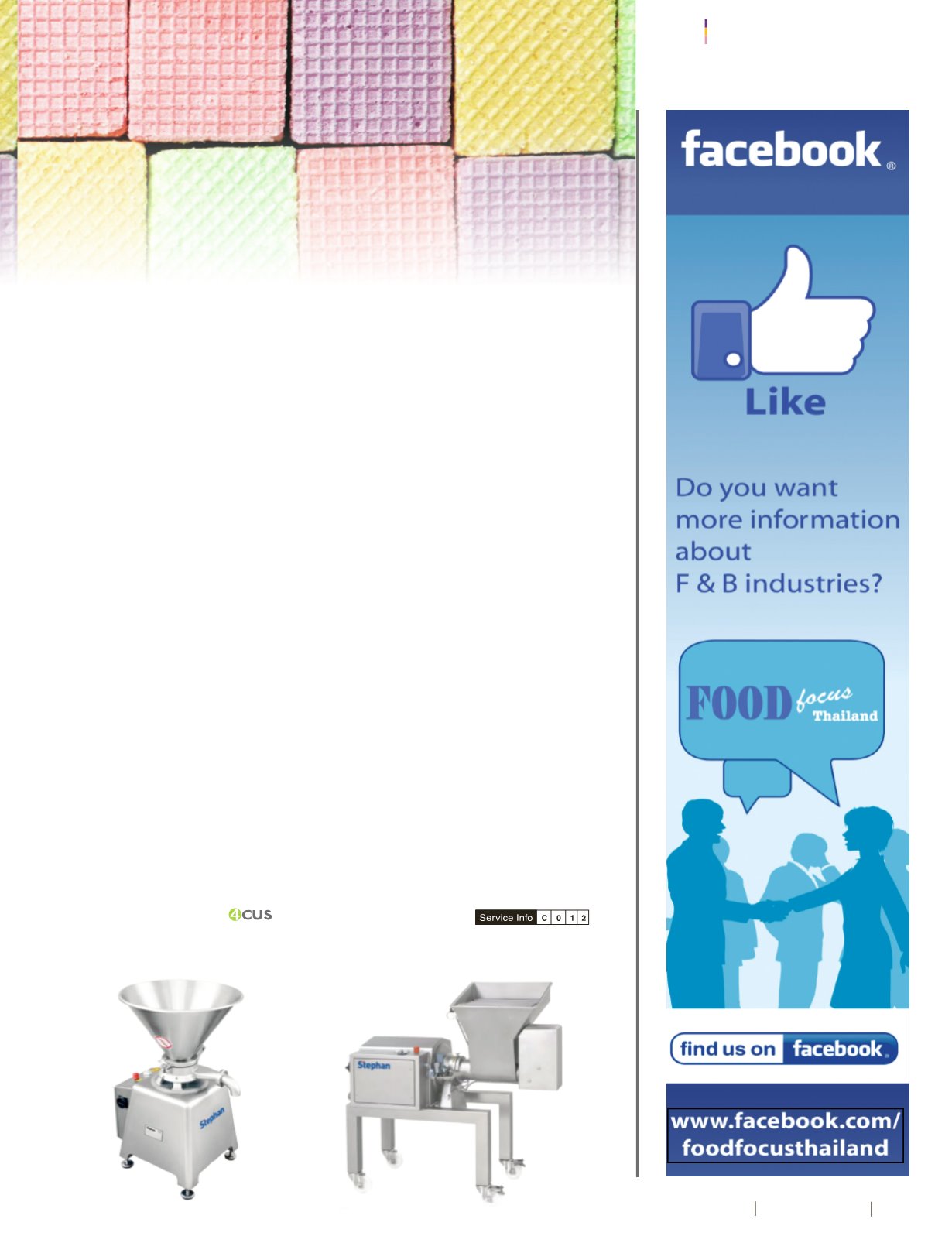

Currently, for product that size reduction andmixing are needed, there are also special

fine cutters that offer amanufacturer to be able to control the particle size of product by as

easy as just choosing the cuttinggapof knife ring. Tohelpavoidingproduct burnduring fine

cutting process, the knife ring is specially designed in “non-metal tometal contact” concept

shown in figure3. Theproduct canalsobemixedhomogenously by this kindof knives. This

machine can be used in the rework process of wafer, snack, cookies and biscuit. The result

is very good. The texture will be in a powder-like formwithout any lump issue. In the end,

thementioned technologies are particularly interesting for sweet and confectionery industry

both nowand in the future.

ANewMixingandCookingBowlFOR

Snack

and

Confectionery

Sweet and confectionery manufacturing process is quite complicated,

needs a lot of space and workers, and takes a long time to produce,

especiallywhenusing the conventional cookingbowl in theopenair and

under normal atmospheric pressure. This process also requires high

cooking temperature, and a long processing time which flavour, texture

andnutrients canbe lost from this kindof processing.