STAND OUT

TECHNOLOGY

97

JUN 2017 FOOD FOCUSTHAILAND

The quality assurance plays a significant role in analyzing and

monitoring of such safety for consumers. And since UHT products

canbe consumedwhenever theywant, the inspectionagency need

toworkagainst time toensure thatUHTproductswill bedelivered to

customers in time,butstillmaintain thegoodquality inspectionbefore

theproductsarehanded tocustomersorconsumers.However, rapidly

testing report not only helps manufacturers have greater business

opportunities by releasing products to the market, but it can also

reduce the storage space and amount of inventory. This also helps

reduce cost in overall including labor cost, inventory management

cost, and business opportunity cost, andetc.

TheMicroorganismAnalysisMethod

for UHTProducts

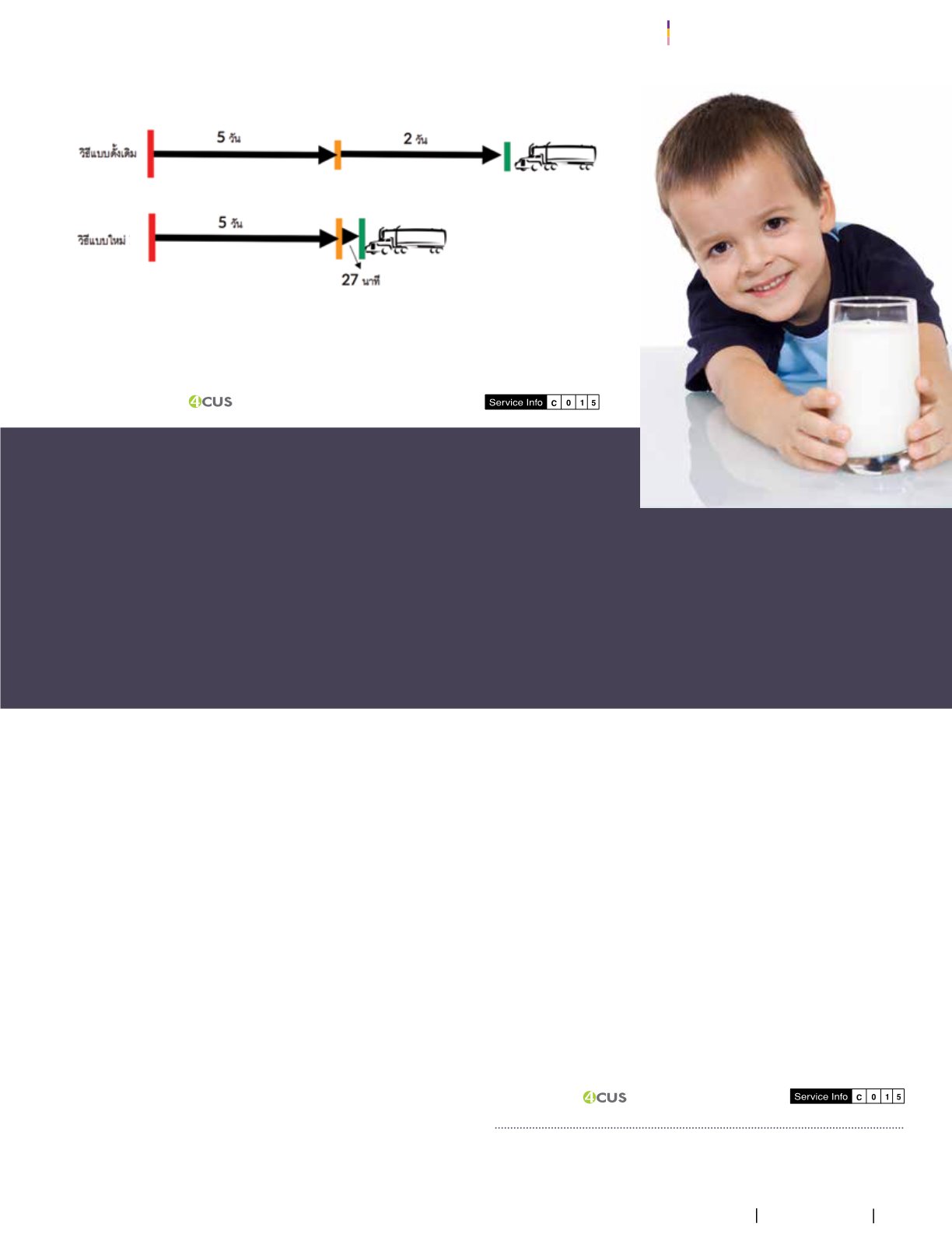

In general, themethod of microorganism analysis inUHT products

is divided into two steps. The first step is the pre-incubation. It is an

important step for UHT-based products because this system can

destroymicroorganisms,pathogensand foodspoilagemicroorganisms

that grow rapidly at room temperature.As a result, even there is no

microorganisms left,but theremaybeacontamination revertedback

to the products. Therefore, it is required to increase the number of

microbes that can be detected bymicrobiology method. Under the

method,microorganism inUHTproductswill be incubatedat least 5

days.Thesecondstep is themicrobiological testing.Currently, there

The Notification of the Ministry of Public Health (No. 349), B.E.2556, Re: Methods, Equipment and Storages for

ManufacturingofThermallyProcessedLow-acidFoodsandAcidifiedFoodsPackaged inHermeticallySealedContainers

has regulated a control of UHT processing and finished products, while also stringently controlled of the production

quality under suitable self-monitoring system in order to help reduce and eliminate the hazards that contaminated to

consumers.

are two isolation methods including pour plate and streak plate. The

methods takemore than twodays forexamination;startwithpreparation,

inoculationanddilutionaswell as incubation,whichwill needmore than

7 days to report themicrobiological testing.

Testing InnovationwithRapidMethod

The rapidmicrobial detection system

1

that usesATPBioluminescence

is an innovative technology and allows rapid assessment of UltraHigh

Temperature Processing (UHT) or Extended Shelf Life (ESL) milk and

sterilized dairy samples that have already been incubated within their

pack. With mentioned system, it will help reduce processes of

microbiological testing, which can reduce the duration of the test from

twodays to less than27minutes.Theoperatingsystemof theautomatic

instrumentmanages throughsoftware.The instrumentwillhaveaprocess

toeliminateATPof thesamplingproductbyusingATPaseenzyme.After

that thecontaminatedcellsofmicroorganismswill bebroken,whichwill

release ATP, and cause sudden light by a reaction between ATP and

LuciferinsubstrateswithLuciferaseenzymes.Finally, the last step is the

censorship of light power. All of those steps will be processed

automatically.

ข้

อมู

ลเพิ่

มเติ

ม / Additional Information

1

3MMicrobial LuminescenceSystem II (MLS II) ระบบการทดสอบเชื้

อจุ

ลิ

นทรี

ย์

โดยอาศั

ย

หลั

กการตรวจATP

1

3MMicrobial LuminescenceSystem II (MLS II) a rapidmicrobial detection system

that usesATPBioluminescence

ออกไปโดยใช้

เอนไซม์

ATPaseจากนั้

นจะท�

ำให้

เซลล์

ของเชื้

อจุ

ลิ

นทรี

ย์

ที่

ปนเปื

้

อนแตกออกซึ่

งจะปลดปล่

อย

ATPออกมาและจะมี

การท�

ำให้

เกิ

ดแสงโดยการท�

ำปฏิ

กิ

ริ

ยากั

นระหว่

างATPกั

บซั

บสเตรทLuciferin และ

เอนไซม์

Luciferaseและขั้

นตอนสุ

ดท้

ายคื

อการตรวจวั

ดพลั

งงานแสงที่

เกิ

ดขึ้

นซึ่

งทุ

กขั้

นตอนที่

กล่

าวมานี้

เกิ

ดขึ้

นอย่

างอั

ตโนมั

ติ

Innovation

forRapidMethodof

UHTProduct Inspection

Pre-Incubation

MicrobiologyTest

Pre-Incubation

1