SPECIAL

FOCUS

37

JUL 2017 FOOD FOCUSTHAILAND

“Et bliev nix wie et wor” (“Nothing stays as it was”): that’s the

wordingofArticle5 in theKölschConstitution,acompilationofeleven

idioms in the localdialect.And thatalsoapplies to theCologne-based

brewery Privatbrauerei Gaffel: capacities in its previous inner-city

facilitywereexhausted–morespacewasurgently required.Needless

tosay, the family-managedbrewerywanted tokeep its independence

andcontinue toproduceefficiently.SoGaffel tookaboldstep towards

an auspicious future – and merged its two breweries into a single

plant.

It was not so very long ago that Privatbrauerei Gaffel was still

operating twobreweries:since1908, ithadbeenbrewing its traditional

Gaffel-Kölsch right in theheart of Cologne’s inner city, just a stone’s

throw away fromCologneCathedral. And in 1998, it then took over

theRichmodis-Brauerei in thesuburbofPorz-Gremberghoven.Kegs

and “Pittermännchen” (10-litre Kölsch barrels), moreover, are filled

inCologne’s northernBilderstöckchendistrict.

But it was precisely this inner-city location that entailed a few

problemswhich are firstly supplying the brewerywith rawmaterials

and expendables, as well as tanker-truck traffic, grew into a

progressively more difficult logistical challenge, and secondly the

space constraintsentailedby the fact that thebuilding complexwas

located in themiddleof a street near Cologne’smain stationdidnot

permit any expansion. On amere 2,000 squaremetres, Gaffel was

brewingalmost half amillionhectolitres a year.

So therewas only one logical consequence forGaffel: tomerge

its three facilities intoone in themedium term.Thepremisesofwhat

used to be the Richmodis Brewery were downright predestined for

thisplan. Not onlywas theautobahnonly a short distanceawaybut

theexisting infrastructurewas likewisewell-nigh ideal: theproduction

facility is situated in a designated industrial estate –

there are no problems about producing round the

clock there.What’smore, thepremisespossess their

owndeepwellwithcertifiedwater rights.So thiswas

a no-brainer.

TurnkeySolution

No sooner said thandone. Back in2012, Gaffel had

already started tomake plans for the relocation, put

it out to tender in thenormalwayamong thevendors

ofbreweryprocess technology–and in theendopted

for one of the best turnkey solution provider for

breweries

1

. “It was not really the most favourable

quotationbut itdefinitelywas thebestoverall technical

solution,” says Reiner Radke, Technology and

LogisticsDirector,andemphasisesa fewmajorpoints

inaddition: “We’re largely usingdouble-seat valves

2

Additional Information

1

KronesAGa leading turnkey solutionprovider for breweries

2

Evoguarddouble-seat valves andpumps

3

Steinecker brewing system

4

BotecF1process control systemwith integratedSiemens-S7 technology

5

Steinecker TFSTwinFlowSystem

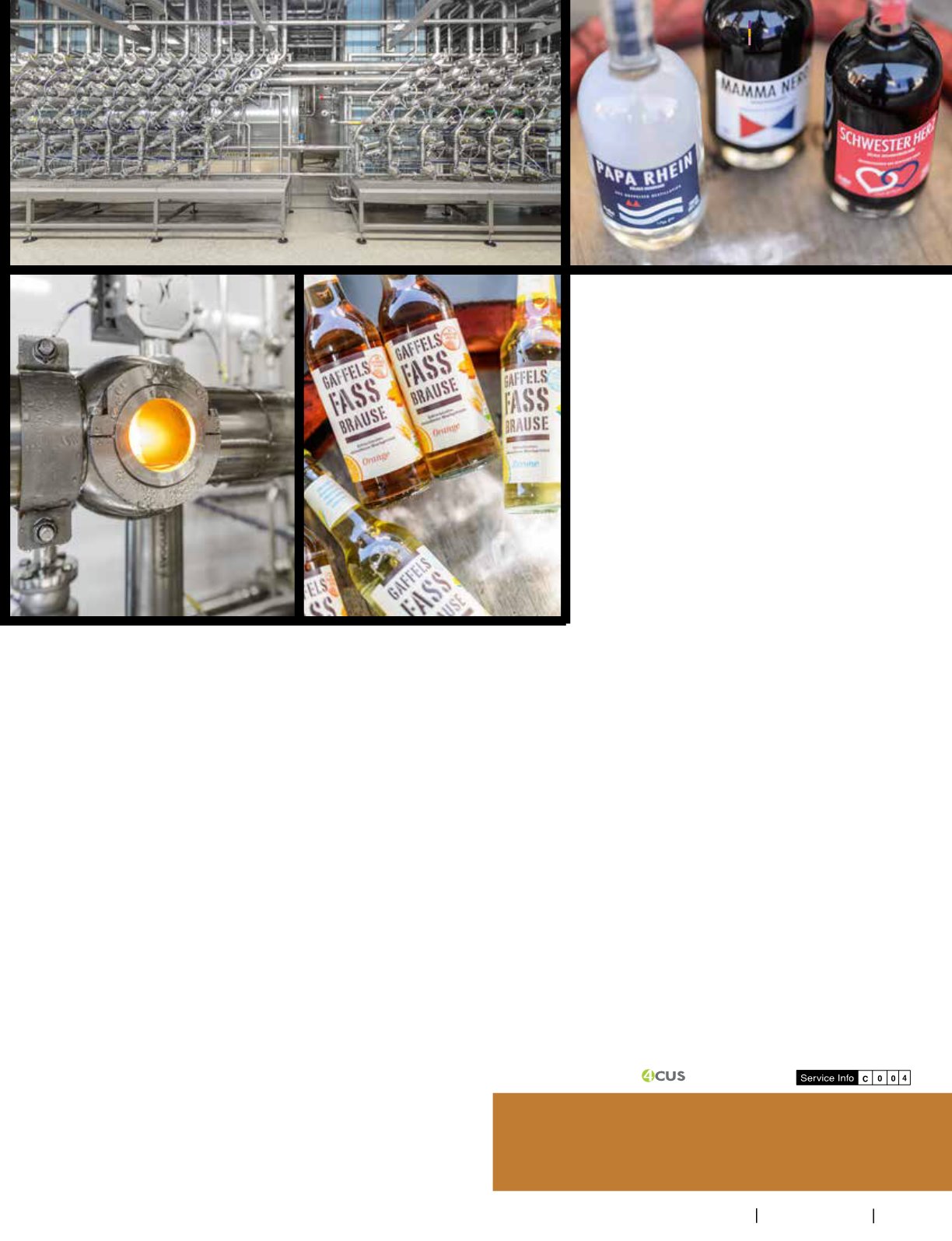

throughoutourproductionoperation.Thesearesubstantiallysmaller than

competitors’ models, and all the components can be replaced without

having touse special tools. Similar considerationsapply for thepumps

2

,

which additionally consume less energy than comparable units. What’s

more, our staff were already familiar with the equipment; the existing

brewingprocess

3

installed inourRichmodisbrewhouse, and theprocess

control systemwith an integrated technology

4

installed in our Eigelstein

facility.”

SoGaffel placedanorder toaprovider fora turnkeysolution

1

, except

for thenewboilerhouse,which thebrewery installed itself.Gaffelwanted

tokeeponusingsomeof theexistingRichmodiskit, andsupplement this

withnewunits.Theonlycomponents thatGaffel tookalong from itsoriginal

brewery in theheartofColognewereasheetfilteranda twinflowfiltration

system (TFS)

5

. “Wewanted to keep the sheet filter becausewe’re filling

incold-sterilemode–noflashpasteurizationeven, letalonepasteurisation

proper,” explainsReiner Radke. “We took a deliberate decision against

membranefiltration foravarietyof reasons, oneof thembeing thatwe’re

assumingwe’ll beable to run theTFSwithcellulose insteadof diatomite

in the not toodistant future.”

Article 10 of the Kölsch Constitution reads: “Drinks de ejne met?”

(“Like tohaveadrinkwithus?”)–ReinerRadke’sanswer to thisquestion

can meanwhile be a confident “Yes”, now that this project has been

successfully concluded.