48

OCT 2017

FOOD FOCUSTHAILAND

SMART

PRODUCTION

andsolidvacuum-sealedmaterials.Theoperationfirstly involves loading

of foodsamples into thecylindricalpressurevessel.Withsolidpackages,

apressurising liquid issuppliedby lowpressurepump.Then thedesired

pressure is achieved either by an intensifier or high-pressure pump, or

bydirectcompression throughahydraulicsystem.Afterholding thehigh

pressure for the required time, the vessel subsequently releases the

medium todecrease thepressureand theproduct isunloaded from the

machine.

The continuous system, however, can process only liquid or

pumpable materials. The products flow from a storage vessel into an

open-endchamber,pressurisedat100MPaormorebyahigh-pressure

intensifier, then intoa sterile vessel andeventually intoa filling station.

Practically, this type of HPP generates shearing and frictional forces

fromflowconditions,whichcontribute toasignificant rise in temperature

of the treated liquid. Inorder toavoid thermal effects fromcompression

and decompression, the semi-continuous system can be performed

instead.

Similar to the batch system, the semi-continuous system allows

products to be compressed in a close vessel. Firstly, a low-pressure

pump loads liquid products into isolated chambers, which are high-

pressurepumpedandhold.Eachchamber thenseparately releases the

product intoa central surge tank and finally a filling station.

HPP inBusiness

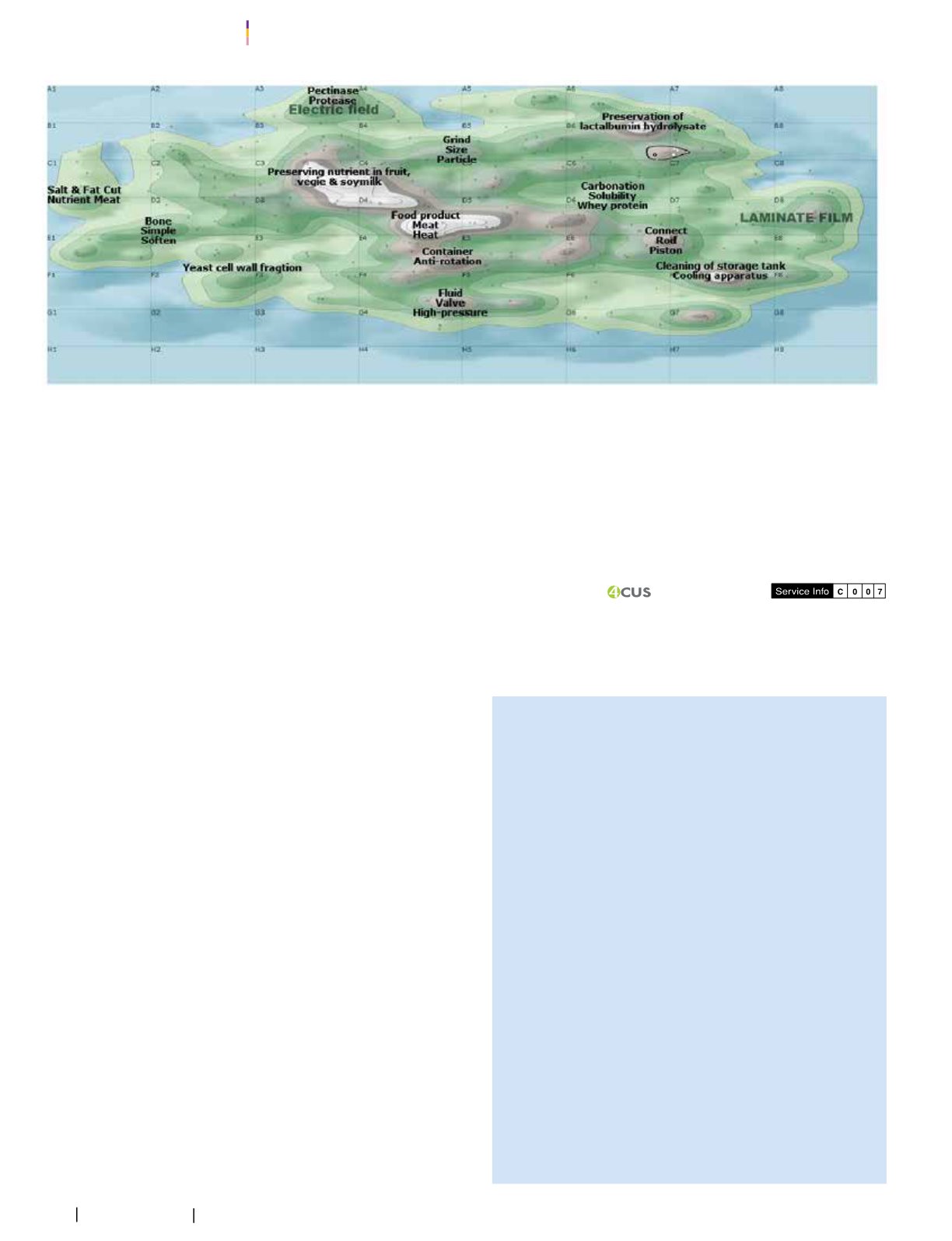

Theoverallactivitywithinhighpressure foodprocessingpatent landscape

has considerably increased over the last ten years, from 166 patents

during theyear2007-2011 to331patents in2012-2016.China, theU.S.,

SouthKorea,andJapanareprimarysourcesofHPPpatent registrations

(Table4).Textmininganalysisofapatentcollection (1997-2016) reveals

a variety of research topics andapplications related toHPP in the food

industry.Many inventionsare related to food treatments,especially liquid

foodpreservation, forexample,soymilk treatmentwithpreserved linoleic

acid, fruit processing with preserved probiotics, low-sodium ham

treatment, and milk and whey protein processing with preserved

lactalbuminhydrolysate. Inventions related toengineering improvement

are anti-rotation food containers in high-pressure tubes, high-pressure

hot vapour for cleaningof storage tanks, and temperatureandpressure

sensors.

รู

ปที่

4

แผนภาพการจดสิ

ทธิ

บั

ตรกระบวนการถนอมอาหารความดั

นสู

ง (2540-2559)

viii

Figure 4

Patent landscapeof highpressure foodprocessing (1997-2016)

viii

Atpresent,HPPsystem iscommerciallyavailable throughseveral

suppliers

3

. It has been distributed to companies, universities, and

research institutes around theworld, includingThailandwhereHPP

system iscurrentlybeingdeveloped for industrial packaged foodand

beverages. Although the cost of infrastructural investment in this

technology is still expensive, it reveals potentials in the production

of high value foodwhich serves growing demands from consumers

around theworld.

ข้

อมู

ลเพิ่

มเติ

ม/ Additional Information

1 การใช้

อุ

ปกรณ์

ALSTOM’sHyperbar เพื่

อผลิ

ตแฮมแผ่

นในประเทศสเปน

2 การผลิ

ตน�้

ำส้

มและน�้

ำเกรพฟรุ

ตโดยใช้

ระบบของบริ

ษั

ทULTI ประเทศฝรั่

งเศส

3 ในปั

จจุ

บั

นระบบHPPสามารถหาซื้

อได้

จากผู

้

ผลิ

ตหลายราย เช่

นHyperbaricUSA,

Febix International Co., Ltd., AvureTechnologies, Inc.

i

ii Rastogi, N. K., et al. “Opportunities andchallenges inhighpressure

processingof foods.” Critical reviews in food scienceandnutrition47.1

(2007): 69-112.

iii SanMartin, M. F., G. V. Barbosa-Cánovas, andB. G. Swanson.

“Foodprocessingby highhydrostaticpressure.” Critical Reviews in

FoodScienceandNutrition42.6 (2002): 627-645.

iv Elamin,WaelM.,etal. “HighPressureProcessingTechnologyandEquipment

Evolution: AReview.” Journal of EngineeringScienceandTechnology

Review8.5 (2015): 75-83.

v Butz, P., andB. Tauscher. “Emerging technologies: chemical aspects.”

Food research international 35.2 (2002): 279-284.

vi Oey, Indrawati, et al. “Effect of high-pressureprocessingoncolour, texture

and flavour of fruit-and vegetable-based foodproducts: a review.” Trends

inFoodScience&Technology 19.6 (2008): 320-328.

vii Patras,Ankit, et al. “Impact of highpressureprocessingon total antioxidant

activity, phenolic, ascorbicacid, anthocyanincontent andcolour of

strawberry andblackberry purées.” InnovativeFoodScience&Emerging

Technologies 10.3 (2009): 308-313.

viii Thomson Innovation วิ

เคราะห์

โดยศู

นย์

ข้

อมู

ลและการคาดการณ์

อนาคต

จากจ�

ำนวน631กลุ่

มสิ

ทธิ

บั

ตรDerwentWorldPatents Index (DWPI)