32

AUG2016

FOOD FOCUSTHAILAND

SPECIAL

FOCUS

3. Analyze the existing plant

layout to find inherent problems

and deficiencies, which can then

serveasguidelines for changesand

modifications.

4. Create new and improved

factory layout whichuse the study’s

findings to implement greater

efficiencies for theplant’sproduction

processes.

5. Compare results of the

existing plant layout and the new

factory layoututilizing thesimulation

programArena.

6. Present the proposed factory

layoutmodifications to thecompany,

and explain their benefits and how

they can be implemented in actual

production processes, along with

allowing the research team tocollect

data.

7. Present the collected data

comparing results before and after

the improvementprocessalongwith

conclusions and recommendations.

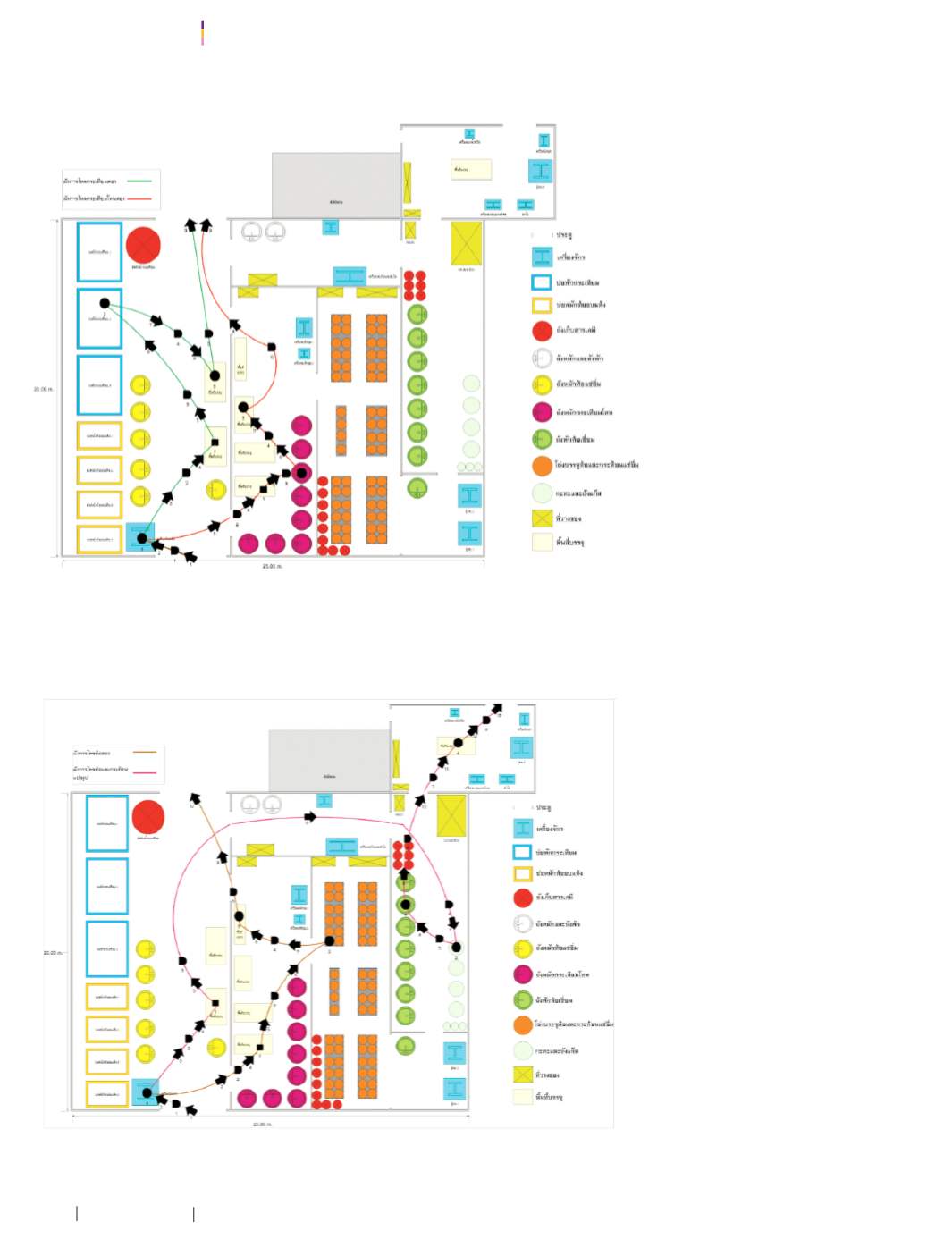

From studying the production

processes and analyzing the

relationship of the work stations, a

Relationship Diagram was created

and an overall score of proximity,

or Total ClosenessRatings (TCRs),

was calculated (Table 1). Making

analyses with use of the Arena

simulationprogramhelped implement

greater efficiencies within the plant

layout for themanufacturingprocess

by reducing production process

distances and the time needed for

moving materials while increasing

usable production process areas

and creating the greatest benefits.

With regard to the improved factory

layout, the application of technical

designmethods resulted in amore

efficient new plant layout. Figure 1

and 4 shows the original and new

plant layouts.

The research team got the

good support from the company.

Thenewplant layout helped reduce

production time for pickled garlic

6.06 percent, and the distance

used for the movement of raw

materialsduringprocessingdropped

1.28 percent. Time needed for the

production of pickled single garlic

was reduced 6.08 percent, and the

รู

ปที่

2

แสดงการไหลของกระเที

ยมดองและกระเที

ยมโทนดอง

Figure 2

Showing the flow of pickledgarlic and pickled single garlic

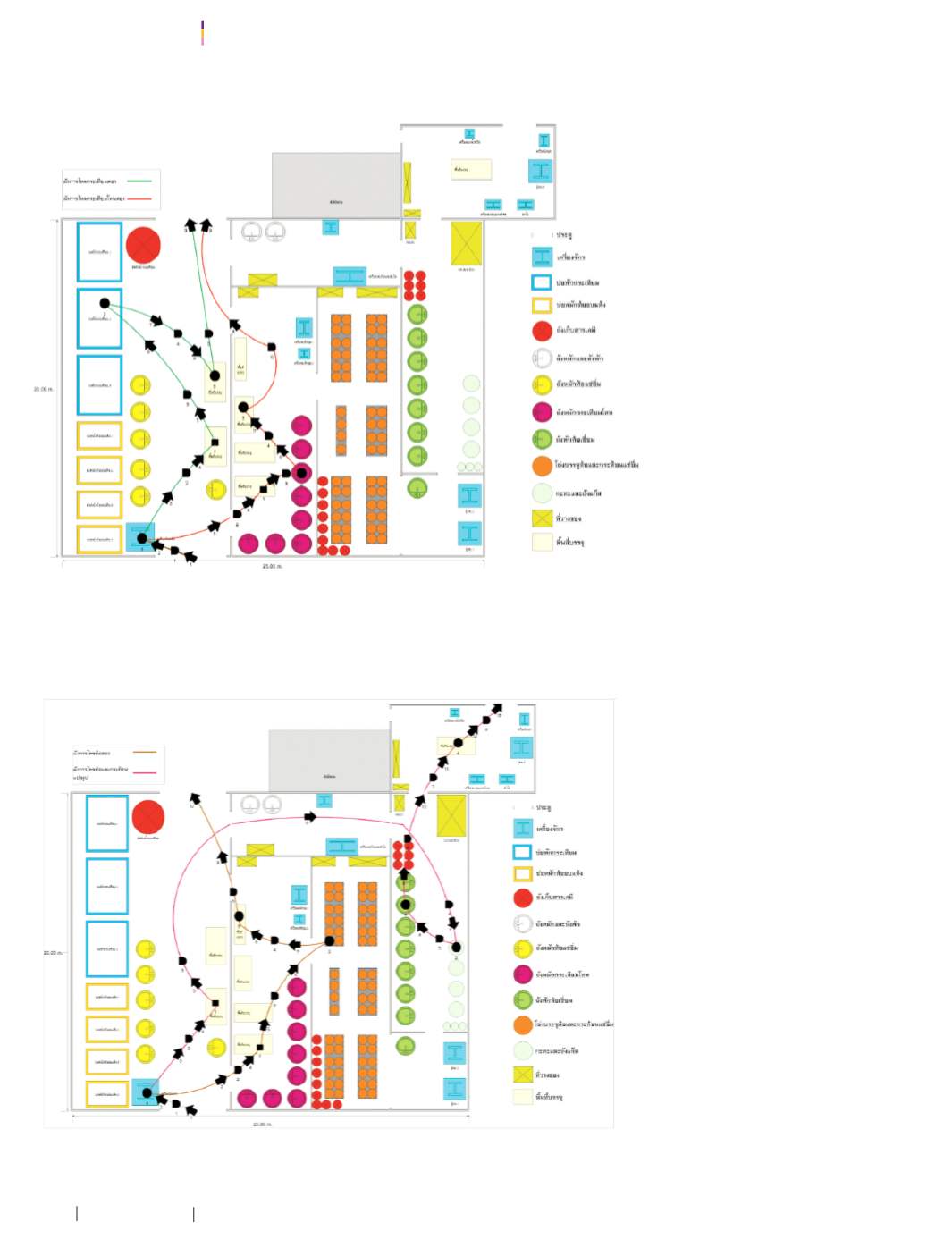

รู

ปที่

3

แสดงการไหลของท้

อดอง และท้

อหรื

อกระท้

อนแปรรู

ป

Figure 3

Showing the flow of pickledpeach and processedpeachor processed santol